Research Equipments

Manifold Gas Injection Kit with Open ECU and EGR

(Product Code: R&DU01)

Components of GAS Open ECU with EGR

- Crankshaft position sensor (Measures crankshaft position)

- Camshaft position sensor - (Measures camshaft position)

- MAF Sensor - (Measures mass air flow)

- Map sensor - (Measures manifold temperature and pressure)

- Engine Control Unit - (To Measure sensors and control series of actuators on an internal combustion engine and ensure excellent engine performance)

- Gas injector – (For fuel injection)

- EGR Valve - (Re-circulates controlled flow of exhaust gas into the intake)

- Can + K line - (For calibration and Troubleshoot)

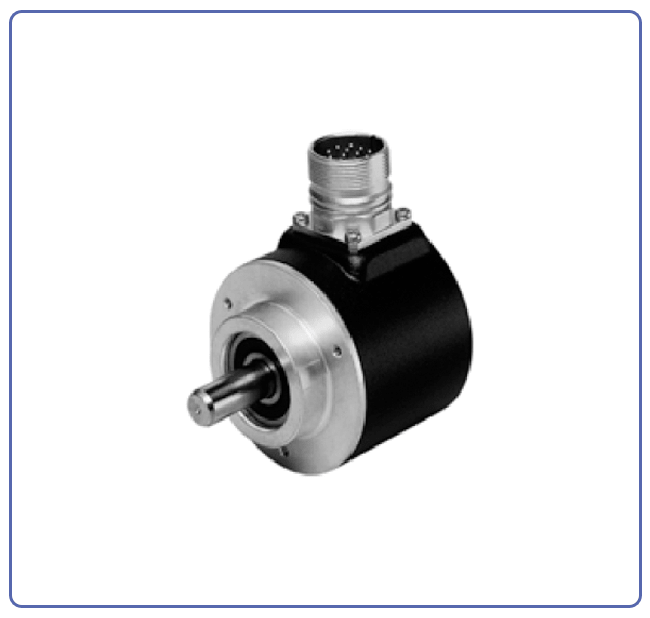

Engine Crank Angle Encoder

(Product Code: R&DU03)

Features

- Extensive range of Experiments

- Comprehensive teaching manual

- One year warranty

- Esthetically designed and finished Rig.

- High Quality instrumentation

Engine Crank Angle Encoder

(Product Code: R&DU03)

Features

The Engine Combustion Analyzer kit is a reliable tool to examine the combustion process of an internal combustion engine. This rugged, compact instrument provides the user with an efficient and effective method to evaluate and determine power cylinder combustion characteristics, and peak pressure balance. The engine combustion analyzer kit includes Software, combustion pressure sensor, and Crank Angle Encoder.

Exhaust Gas Recirculation System

(Product Code: R&DU06)

Product Description

In the present system the Exhaust gas coming out of the engine is passed to an EC (Exhaust cooler). The exhaust gases from the EC after cooling are passed via a valve and digital manometer. The digital manometer is provided in order to find the total amount of exhaust gas flow (when the EGR Control Valve is closed) and valve for controlling the flow. The digital manometer operates within the temperature range of 10- 50ºC; this is the reason for cooling the exhaust gas after the EGR system. In the main Exhaust line a tapping is provided for EGR system. The Exhaust gas from the tapping via a (stepper motor controlled) valve and is passed to the EGR Cooler, where the exhaust gas is cooled before sending it to the engine. A digital manometer is provided at the inlet manifold of the engine in order to know the flow of Exhaust gas to the engine. To allow desired percentage of EGR into the engine, the first step we should find the total flow of exhaust gas with the digital manometer provided after the EC. If the flow is supposing 40mm, therefore 40mm is the 100% at some particular load. If we wise to pass 10% EGR, now the EGR Control valve is slowly opened until we reach 4mm reading in the digital manometer provided at the intake manifold of the engine.

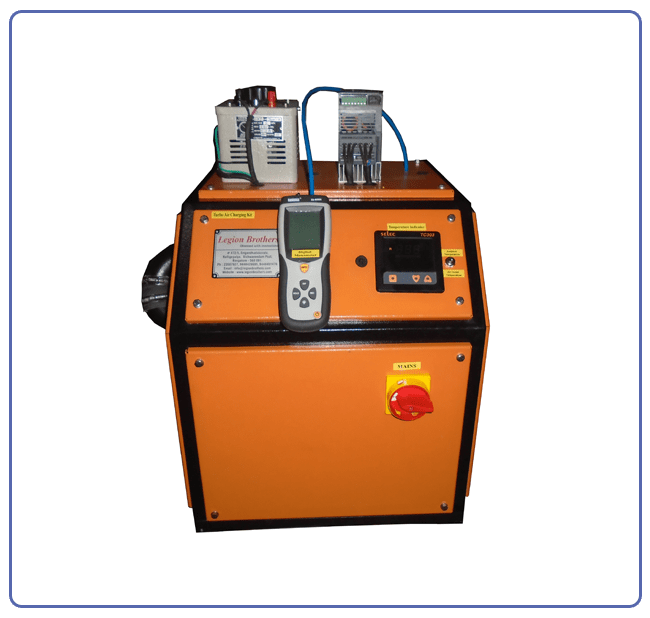

Turbo Air Charging System with Air Heating

(Product Code: R&DU10)

Product Description

The purpose of turbo charging is used for forced-induction of an internal combustion engine and to increase the density of air entering the engine to create more power. The system consists of a 3HP turbine blower connected with a variable Speed AC frequency drive. The outlet of the turbine blower is routed to the intake manifold of the engine via an Air Heating system, digital manometer, valve (V2), and finally to the engine intake manifold. A temperature sensor is also provided in the engine manifold to know the temperature of incoming air to the engine. Before using the turbo air charging system to the engine, the engines air consumption at different loads should be MAPPED. Whenever a turbo air charging system is not required Valve (V2) should be closed and valve (V1) should be in open condition.

Turbo Air Charging System with Air Heating

(Product Code: R&DU10)

Features

- Extensive range of Experiments

- Comprehensive teaching manual

- One year warranty

- Esthetically designed and finished Rig

- High Quality instrumentation

Data Acquisition System for IC Engine Performance Testing

(Product Code: R&DU12)

Product Description

Most modern engines today are controlled by an onboard computer, for purposes like Engine Operation, Optimization, Safety, Fuel efficiency, Pollution control etc… be it any purpose, the primary process of all such control systems is collecting and processing real world data. This is a device designed for measuring, processing and transferring engine test data to any computer, such data is primarily intended for educational and research use. It consists of Data Acquisition module; Sensors for IC engine performance testing, Sensor mounting accessories, Windows based computer software and Inter connecting cables, facilitating it to be readily installed on your existing petrol or diesel engines.